Machine Engines: 3204 3208 3304 3306 3406 3408 3412

- Industrial Engines:

- 3204 (S/N: 3PC1-UP)

- 3306 (S/N: 64Z1-UP)

- 3306B (S/N: 7JB1-UP; 5GZ1-UP)

- 3408 (S/N: 67U1-UP)

- 3412 (S/N: 9XF1-UP)

- 3412C (S/N: 38S1-UP)

- Generator Engines:

- 3208 (S/N: 29A1-UP; 30A1-UP)

- 3304B (S/N: 9HK1-UP)

- 3306 (S/N: 85Z1-UP)

- 3306B (S/N: 2AJ1-UP; 8JJ1-UP; 9NR1-UP; 9DS1-UP)

- 3406B (S/N: 2WB1-UP)

- 3406C (S/N: 4RG1502-UP; 4JK99-UP; 4ZR1-UP; 1SS1-UP; 8FS1-UP)

- 3408C (S/N: 78Z4867-UP)

- 3408B (S/N: 78Z1-4866)

- 3412C (S/N: BAK1-UP; BAX1-UP; 81Z1-UP)

- 3304 (S/N: 83Z1-UP)

- 3412 (S/N: 2WJ1-UP)

- 3406 (S/N: 4RG1-1501; 4JK1-98)

- Truck Engines:

- 3208 (S/N: 02Z1-UP; 51Z1-UP)

- 3306B (S/N: 63Z1-UP; 5KD1-UP)

- 3306C (S/N: 7RJ1-UP; 3KS1-UP; 9TL1-UP)

- 3406B (S/N: 8TC1-UP; 7FB1-UP; 5YG1-UP; 4MG1-3599)

- 3406C (S/N: 3ZJ16182-UP; 5KJ7800-UP; 8PN1-UP)

- 3406 (S/N: 3ZJ1-16181; 5KJ1-7799; 4CK1-845)

- 3408 (S/N: 28V1-UP)

- Marine Engines:

- 3208 (S/N: 75V1-UP; 01Z1-UP)

- 3304 (S/N: 13E1-UP)

- 3304B (S/N: 1PS1-UP; 1NS1-UP)

- 3306B (S/N: 1RS1-UP)

- 3408B (S/N: 8RG1-UP)

- 3408C (S/N: 99U1-UP; 1TS1-UP)

- 3412 (S/N: 3JK146-UP)

- 3412B (S/N: 3JK1-145)

- 3412C (S/N: 60M1-UP; 9BR1-UP)

- 3412D (S/N: REA1-UP)

- 3306 (S/N: 84Z1-UP)

- 3406 (S/N: 4TB1-UP)

Introduction

This Special Instruction has been written in order to provide procedural

information for testing 7000 Series fuel nozzles.

There is an extensive amount of information that relates to the setup and the

calibration of the tools that will be used to test the fuel nozzles.

Additionally, there is information on the setup and operation of the cleaning

equipment that is necessary in order to clean the fuel nozzles.

There is also a publication that provides record sheets. These record sheets

can be used for recording and correlating the test data that is accumulated. The

following information will summarize the related documentation.

- For information on the setup, operation, and the calibration of the test

equipment, refer to Tool Operating Manual, SEHS7292, "Using the 5P-4150 Nozzle

Testing Group".

- For information that relates to the setup and operation of the tools that

are used to clean fuel nozzles, refer to Special Instruction, SEHS8627, "Using

the 8S-2245 Nozzle Cleaning Tool Group".

- Use the Special Instruction, SEHS8144, "Engine Nozzle Test Record" in

order to record the results while you are testing each fuel nozzle. These

record sheets are available through normal channels for literature

distribution. The record sheets are available in pads that contain 50 sheets.

Note: The publications that are mentioned above may contain

information that must be referenced in order to test the fuel injection nozzles.

Testing 7000 Series Fuel Nozzles

|

|

Ensure that you wear eye protection at all times during testing. When

fuel injection nozzles are tested, test fluids travel through the orifices

of the nozzle tip with high pressure. Under this amount of pressure, the

test fluid can pierce the skin and cause serious injury to the operator.

Always keep the tip of the fuel injection nozzle pointed away from the

operator and into the fuel collector and extension. |

|

|

| NOTICE |

|

Always ensure that the test fixture is in proper working order. Check

that the fluid reservoir contains clean test fluid. Failure to do so may

damage the fuel nozzles that you are testing and will reduce the life of

the test equipment. |

|

Note: Prior to starting this test procedure, the 5P-4150 Nozzle

Testing Group must be equipped with a 8T-0860 Pressure Gauge . Replace

the original 8T-0859 Pressure Gauge with the 8T-0860 Pressure

Gauge . Refer to Tool Operating Manual, SEHS7292, "Using the 5P-4150 Nozzle

Testing Group" for information that relates to the replacement of the pressure

gauge.

Inspect the Fuel Nozzle for Damage

Perform a visual inspection of the fuel nozzle. Inspect each fuel nozzle for

any sign of damage that may contribute to the improper operation of the fuel

nozzle. Check for signs of damage that may have been caused by any of the

following conditions:

- Engine overheating (discolored fuel nozzles)

- Improper cleaning (use of a wire brush for cleaning)

- Partially melted carbon dam seal

- Fuel nozzles that are deformed or bent

- Cracking or splitting of the nozzle tip

- Other obvious damage

Note: If there are signs of engine overheating, all of the fuel

nozzles must be replaced.

If any of these forms of damage has been found, do not use the damaged fuel

nozzle.

Install the Fuel Nozzle onto the Test Fixture

Note: Be sure to check the test fixture for leaks prior to performing

this test procedure. Refer to Tool operating Manual, SEHS7292, "Using the

5P-4150 Nozzle Testing Group" for information that is related to the operation

of the nozzle testing group.

- If the fuel nozzle is equipped with a purging screw, remove the purging

screw and seal washer from the fuel nozzle.

|

|

|

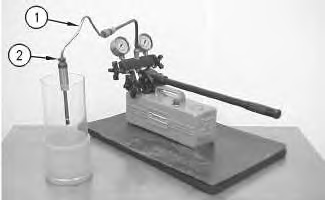

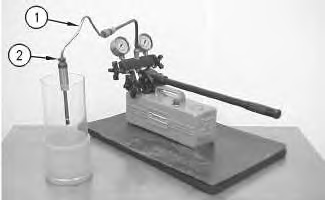

| Illustration 1 |

g00945947 |

- Install tube assembly (1) and nozzle adapter (2) onto the test fixture.

Refer to Table 1 for the correct tube assembly and the correct fuel nozzle

adapter to use for your application.

Table 1

| Tool Requirements for 7000

Series Fuel Nozzles |

| Engine Family |

Tube Assembly |

Fuel Nozzle Adapter

|

| 3200 |

5P-4721 |

5P-4244 |

| 3300 |

6V-2170 |

5P-7448 |

| 3400 |

5P-4721 |

5P-4244 (1) |

| ( 1 ) |

You must use the FT-1743 Fuel Test Line in order to

properly attach the fuel nozzle to the fuel nozzle adapter. This test

line may be fabricated from the 1W-4660 Fuel Injection Line As

. |

- Position the fuel nozzle onto the tube assembly and hand tighten the

nozzle to the adapter fitting.

- Close the ON/OFF valve.

- Open the pump isolator valve for one-half turn.

- Open the gauge protector valve (0 to 40,000 kPa (0 to 5,800 psi) gauge)

for one-half of a turn.

- Place the 8S-2270 Fuel Collector and the 1U-8857 Extension

Tube under the fuel nozzle.

Bleed the Air from the Nozzle Assembly

- Loosen the adapter fitting at the fuel nozzle.

- Operate the pump handle until test fluid that is free of air bubbles flows

from the threads of the adapter.

- Adjust the orientation of the fuel nozzle to the vertical position and

tighten the adapter fitting. Check the tube assembly and adapter fittings for

leakage.

Valve Opening Pressure Test

- Wrap a clean cloth around the top of the fuel nozzle in order to absorb

any internal return leakage.

- Slowly increase the pressure on the fuel nozzle until fluid begins to flow

from the tip of the fuel nozzle. Record this pressure as the valve opening

pressure of the fuel nozzle.

Refer to the information that is provided in Table 2 in order to evaluate

the results of the test.

Table 2

| Specifications for Valve

Opening Pressure |

| Fuel Nozzle |

Valve Opening Pressure

|

4W-7011

4W-7012

4W-7013

4W-7014

4W-7015

4W-7016

4W-7017

4W-7018

4W-7019

4W-7020

4W-7021

4W-7022

7W-7023

7W-7024

7W-7026

7W-7030

7W-7031

7W-7032

7W-7033

7W-7035

7W-7037

7W-7038

8N-7001

8N-7002

8N-7003

8N-7004

8N-7005

8N-7006

8N-7007

170-5187 |

11,100 to 16,200 kPa (1,600 to 2,300

psi) |

7W-7040

7W-7041

7W-7042

7W-7043

7W-7044

7W-7045

100-7550

100-7551

100-7552

100-7556

100-7557

100-7558

100-7559

100-7560

100-7561

100-7562

100-7563

100-7564

100-7565

100-7600

104-3377

129-1351

167-7489

170-5181

170-5183

171-4093

131-3190 |

13,800 to 18,200 kPa (2,000 to 2,700

psi) |

100-7567

104-9450 (1)

104-9452 (1)

104-9453 (1)

104-9454 (1)

121-4353 |

20,700 to 26,900 kPa (3,000 to 3,900

psi) |

127-9792

127-9793

130-1804

130-1806

130-5187

130-5190

131-0811

131-0812

131-1242

131-1243

131-7937

133-3896

134-0944

|

18,600 to 24,100 kPa (2,700 to 3,500

psi) |

| 154-3198 |

16,500 to 22,100 kPa (2,400 to 3,200

psi) |

| ( 1 ) |

This fuel nozzle uses an internal valve with a two-stage

relief action. During the first portion of the valve movement, an audible

click can be heard and a small amount of fuel will be released. As valve

opening pressure is achieved, the second portion of the valve movement

begins the injection cycle. |

If the fuel nozzle is not within specifications, stop the test and do not use

the nozzle.

Check for Tip Leakage

- Close the gauge protector valve (0 to 40,000 kPa (0 to 5,800 psi)

gauge).

- Flush the fuel nozzle that is being tested by pumping the tester for 3

full strokes.

- Open the gauge protector valve (0 to 40,000 kPa (0 to 5,800 psi)

gauge).

- Use a clean cloth to dry the tip and the body of the fuel injector. All

test fluid should be wiped from the nozzle assembly.

- A clean cloth should be wrapped around the top of the fuel nozzle in order

to absorb any internal return leakage. The cloth should cover the hole for the

purging screw in order to absorb any leakage from the hole.

- Calculate the test pressure that will be used for the tip leakage test.

Use the minimum value of the fuel nozzle's valve opening pressure to

calculate the test pressure for the nozzle that is being tested.

- Subtract a value of 1,380 kPa (200 psi) from the minimum valve opening

pressure for the nozzle.

- Record the result of the calculation as the test pressure that will be

used for the tip leakage test.

- Slowly apply the test pressure, that has been calculated in Step 6, to the

fuel nozzle.

- Close the pump isolator valve. Use the pump isolator valve to adjust the

test pressure and close the valve in order to maintain the test

pressure.

- Hold this test pressure for 15 seconds.

- Count the number of drops of test fluid that drips from the nozzle during

the duration of the test. Open the pump isolator valve in order to release the

pressure on the fuel nozzle when the test is completed.

Refer to the information that is provided in Table 3 in order to evaluate

the results of the test.

Table 3

| Specifications for Tip

Leakage |

| No more than 3 drops in 15

seconds |

If the tip leakage for the fuel nozzle is not within specifications, stop the

test and do not use the fuel nozzle.

Test the Fuel Nozzle for Plugged Orifices

|

.jpg)

|

|

| Illustration 2 |

g00453787 |

|

Types of spray pattern for the 7000 Series fuel

nozzles. |

Table 4

| Identification of Spray Patterns

|

| Spray Pattern (1) |

Engine Family |

Number Of Orifices |

| "1" |

3200 |

Four |

| "2" |

3300 |

Six (2) |

| "3" |

3300 |

Nine (2) |

| "4" |

3400 |

Six |

| "5" |

3400 |

Seven |

| ( 1 ) |

Refer to Illustration 2 for identification of the spray

pattern. |

| ( 2 ) |

The spray orifice is manufactured with a 15° angle that

is measured from the centerline of the fuel injector

body. |

- Close the gauge protector valve (0 to 40,000 kPa (0 to 5,800 psi)

gauge).

- Visually inspect the pattern of the fuel nozzle for a uniform spray.

Note: For this test, each full stroke of the pump should be

performed in less than one second.

- Rapidly increase the pressure on the fuel nozzle until fluid sprays from

the tip of the fuel nozzle.

- Test fluid should spray from the tip of the nozzle in a pattern that is

uniform. Refer to Illustration 2.

- Check the individual spray orifices for partial plugging.

- Use a moderate pump stroke in order to open the valve of the fuel

nozzle.

- During the pump stroke, view the individual spray orifices for partial

plugging.

The test fluid should spray uniformly from all of the orifices.

If an orifice is plugged or the pattern is distorted, clean the fuel nozzle's

orifice(s) and repeat this test. Refer to Special Instruction, SEHS8627, "Use of

8S-2245 Nozzle Cleaning Tool Group" for instructions on tool usage and cleaning

procedures.

Test the Fuel Nozzle for Seal Leakage

Note: Testing for seal leakage is not a requirement for the

104-9450 Fuel Nozzle , 104-9452 Fuel Nozzle , 104-9453 Fuel

Nozzle , or the 104-9454 Fuel Nozzle . Do not perform this test on these

fuel nozzles.

|

.jpg)

|

|

| Illustration 3 |

g00453789 |

|

Typical example of a 7000 Series fuel

nozzle |

- Remove the cloth from the top of the nozzle.

- Prior to performing this test, install a new seal washer on purging screw

(A) and reinstall the purging screw into the fuel nozzle.

|

.jpg)

|

|

| Illustration 4 |

g00453809 |

- Tighten purging screw (D) or purging screw (E) to a torque of 2.2 ± 0.8

N·m (20 ± 7 lb in).

Note: Use a 6V-4980 Torque Screwdriver Tool Group in order to

torque the purging screw.

- Apply a test pressure of 13,800 kPa (2,000 psi) to the fuel nozzle.

Note: Due to the large amount of test fluid that is delivered to the

fuel nozzle, hydraulic lock may prevent the nozzle from opening during this

test. If a hydraulic lock occurs, slowly loosen the adapter fitting in order

to relieve the pressure on the fuel nozzle's valve assembly.

If there is leakage at the purging screw, install a new 8C-3234 Screw

and a 114-3364 Washer as replacement parts. Retest the fuel nozzle for

leaks.

Do not use the nozzle if there is leakage that cannot be repaired at purging

screw (A), upper seal joint (B), or lower seal joint (C) .

Returning Fuel Nozzles to Service

|

.jpg)

|

|

| Illustration 5 |

g00453817 |

Prior to returning fuel nozzles to service, install a new seal washer (3) and

install a new carbon dam (4) on the fuel nozzle (1) .

Use 6V-4979 Carbon Seal Installation Tool (2) in order to install a

new carbon dam (4) .

Table 5 contains part numbers for the replacement of the fuel nozzle's seal

washers.

Table 5

| Seal Washers

|

| Fuel Nozzle |

Washer (Color) |

Washer Thickness |

| 8N-7004 |

4W-3914 (Gray) |

1.27 mm (0.050 inch)

|

4W-7012

4W-7013

4W-7014

4W-7015

|

4W-6060 (Blue) |

3.18 mm (0.125 inch)

|

4W-7018

4W-7019

4W-7020

4W-7021

4W-7022

7W-7045

100-7552

100-7562

100-7563

104-3377

167-7489

170-5181

170-5183 |

7W-4482 (Green) |

3.18 mm (0.125 inch)

|

| 133-3896 |

7W-4483 (Red) |

2.54 mm (0.100 inch)

|

4W-7011

4W-7016

7W-7024

|

7W-4485 (Copper) |

1.27 mm (0.050 inch)

|

8N-7003

7W-7038

8N-7005

100-7559

100-7561

100-7564

104-9450

104-9452

104-9453

104-9454

131-3190

154-3198

170-5187

|

7W-4486 (Violet) |

1.84 mm (0.072 inch)

|

4W-7017

7W-7026

7W-7030

7W-7031

7W-7032

7W-7033

7W-7035

7W-7037

7W-7040

7W-7041

7W-7042

7W-7043

7W-7044

8N-7007

100-7550

100-7551

100-7556

100-7557

100-7558

100-7560

100-7565

100-7567

100-7600

121-4353

127-9792

127-9793

129-1351

130-1804

130-1806

130-5187

130-5190

131-0811

131-0812

131-1242

131-1243

131-7937

134-0944

171-4093 |

7W-4487 (Black) |

1.27 mm (0.050 inch)

|

| 7W-7023 |

7W-8119 (Yellow) |

1.84 mm (0.072 inch)

|

8N-7001

8N-7002

8N-7006

|

8N-4183 (Nylon material) |

1.27 mm (0.050 inch)

|

.jpg)

.jpg)

.jpg)

.jpg)